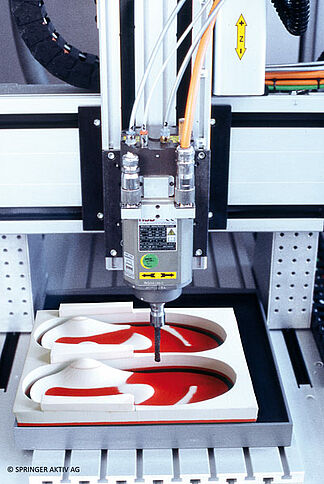

Fabrication – Milling precision

WE USE STATE-OF-THE-ART ANALYSIS TECHNOLOGY FOR DIAGNOSTICS, SIZING AND FABRICATING YOUR FOOT ORTHOSES.

PROPRIO® foot orthoses are generally used for more demanding cases, in which treatment with foot orthoses that relied on passive support did not produce the desired therapeutic outcome. This is one reason why our pedorthists thoroughly analyze each patient’s posture and movement patterns to determine the triggering moments of pain caused by unfavorable joint positions or muscular imbalances. All these measured values then flow into the individualized fabrication of a custom-fit foot orthosis. Now, thanks to modern CNC milling technology, fabrications are possible that previously required hours of tediousness in the workshop: the foot orthosis is designed on the screen precisely to the patient's footprint. It is then fabricated from a soft foam material and milled millimeter by millimeter on a rotating machine head to fit each individual patient’s foot shape and medical indication. In fact, the models for the left and right foot often differ from one another.Depending on the area of application, the soft foam material is characterized by varying degrees of hardness, or Shore hardness, which ensure optimum stimulus uptake and pressure distribution under the sole of the foot.Designing the right model for each patient requires a trained eye and expert knowledge. Pedorthists have acquired these skills through intensive training courses and by earning certification as “sensorimotor therapists”.